ENGLISH

“HŌSYO-TSUMUGI(Dupion Silk Fabric)“

Since the Edo period (1603-1868), the Fukui Domain has been famous for its silk fabrics production.

In the castle town the Samurai (the man who served his feudal lord) and their families used to perform its entire production process starting from sericulture to ”ZAGURI (traditional hand reeling method of Japan)” and then weaving as a part of their home industry.

The fabrics woven there came to be known as “HŌSYO-TSUMUGI” due to its genuine whiteness and beauty that resemble to a kind of Japanese traditional luxury paper called “HŌSYO-SHI”.

The high quality of the textile eventually spread throughout Japan and it was used for the Samurai’s formal attire, Buddhist monks’ robe, and official offerings to Tokugawa Syogunate.

Although fewer people know the fame as of today, this textile laid out the indispensable foundation of the world-famous “HABUTAE SILK” of Fukui prefecture.

“TAMAKOISHI(a Japanese silkworm race)

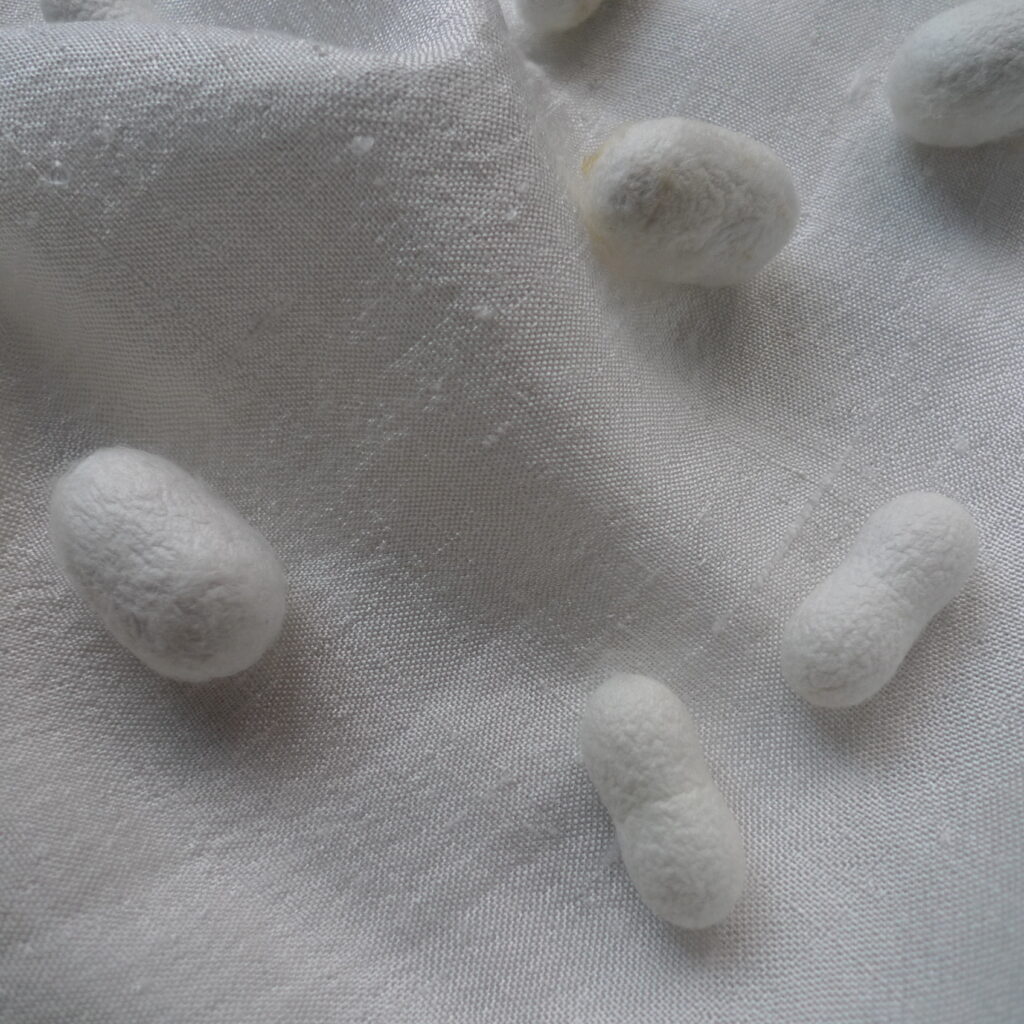

The silkworm race called “TAMAKOISHI” is known for producing delicate, strong, and shining white thread quality inherited from the ancient Japanese silkworm race called “KOISIMARU”.

TAMAKOISHI silkworms efficiently produces “TAMA-MAYU (a cocoons produced by two silkworms by chance as such is normally done by single silkworm)” , and the threads from “TAMA-MAYU” have unique “FUSHI (neps)” which feature allows to hold airy space in-between thread .

However, the amount of threads produced from these TAMA-MAYU cocoons are extremely little, and the

“FUSHI” generally makes it more difficult to process into threads, resulting the final products to be quite rare and precious.

“KINUIRO(features of my studio brand)”

Silkworm Cocoons: The Japanese silkworm race “TAMAKOISI” made in Fukui Prefecture (Sugimoto Sericulture Farmer)

Warp: Single threads with a soft twist made by “ZAGURI” using “TAMAMAYU”

Weft: Single threads with a soft twist made by “ZAGURI” using “TAMAMAYU”

Weaving and Dyeing: Hand –woven and dyed with traditional natural dyes

The above-mentioned entire process at KINUIRO is done by hand.

The reason for this is to bring about the most of the natural texture of silkworm originated threads.

The threads made through “ZAGURI” process are slowly produced by hand enabling the fabric to be elastic and breathable.

Hence, it is soft in texture and tends to be warmer than other fabrics The “FUSHI” created by the threads of “TAMA-MAYU” is particularly airy and warm.

Normally, puffy threads from “TAMA-MAYU” are not used for warp threads because they are considered difficult to incorporate into weaving process.

However, it is my specialty to integrate such threads for warp.

As a result of the interplay between the warp and weft threads, it creates a unique flavor to the fabric created at my studio.

In addition, traditional natural dyeing method is used to bring out the shiny nature that is special to the

“TAMAKOISI”threads.